- info@advance.co.in

- + 91-11- 43041400

"Tirupati" HDPE Pipes are manufactured from virgin raw material and are a cost effective & safe solution for irrigation, water supply ,Industrial application, HDPE Pipes in coil form for submersible pumps etc. These pipes are made under strict quality control & confirm to various IS & International standards

"Tirupati" pipes offer outstanding features which assures low maintenance cost and long term system performance.These pipes are Quite simple, user friendly & easy to fit.

These pipes can be joined by various techniques like socket Fusion,Electro Fusion, Compression & Butt welding.The most popular & accepted form is by Butt welding technique.

| Nominal Diameter | Wall Thickness of Pipes for Pressure Rating of | |||||||||||||

| PN 2.5 | PN 4 | PN 6 | PN 8 | PN 10 | PN 12.5 | PN 16 | ||||||||

| Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | |

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) | (11) | (12) | (13) | (14) | (15) |

| 20 | - | - | - | - | - | - | - | - | 2.3 | 2.8 | 2.8 | 3.3 | 3.4 | 4.0 |

| 25 | - | - | - | - | - | - | 2.3 | 2.8 | 2.8 | 3.3 | 3.4 | 4.0 | 4.2 | 4.9 |

| 32 | - | - | - | - | 2.3 | 2.8 | 3.0 | 3.5 | 3.6 | 4.2 | 4.4 | 5.1 | 5.4 | 6.2 |

| 40 | - | - | 2.0 | 2.4 | 2.8 | 3.3 | 3.7 | 4.3 | 4.5 | 5.2 | 5.5 | 6.3 | 6.7 | 7.6 |

| 50 | - | - | 2.4 | 2.9 | 3.5 | 4.1 | 4.6 | 5.3 | 5.6 | 6.4 | 6.8 | 7.7 | 8.4 | 9.5 |

| 63 | 2.0 | 2.4 | 3.0 | 3.5 | 4.4 | 5.1 | 5.8 | 6.6 | 7.0 | 7.9 | 8.6 | 9.7 | 10.5 | 11.8 |

| 75 | 2.3 | 2.8 | 3.6 | 4.2 | 5.3 | 6.1 | 6.9 | 7.8 | 8.4 | 9.5 | 10.2 | 11.5 | 12.5 | 14.0 |

| 90 | 2.8 | 3.3 | 4.3 | 5.0 | 6.3 | 7.2 | 8.2 | 9.3 | 10.0 | 11.2 | 12.2 | 13.7 | 15.0 | 16.7 |

| 110 | 3.4 | 4.0 | 5.3 | 6.1 | 7.7 | 8.7 | 10.0 | 11.2 | 12.3 | 13.8 | 14.9 | 16.6 | 18.4 | 20.5 |

| 125 | 3.8 | 4.4 | 6.0 | 6.8 | 8.8 | 9.9 | 11.4 | 12.8 | 13.9 | 15.5 | 16.9 | 18.8 | 20.9 | 23.2 |

| 140 | 4.3 | 5.0 | 6.7 | 7.6 | 9.8 | 11.0 | 12.8 | 14.3 | 15.6 | 17.4 | 19.0 | 21.1 | 23.4 | 26.0 |

| 160 | 4.9 | 5.6 | 7.7 | 8.7 | 11.2 | 12.6 | 14.6 | 16.3 | 17.8 | 19.8 | 21.7 | 24.1 | 26.7 | 29.6 |

| 180 | 5.5 | 6.3 | 8.6 | 9.7 | 12.6 | 14.1 | 16.4 | 18.3 | 20.0 | 22.2 | 24.1 | 27.1 | 30.0 | 33.2 |

| 200 | 6.1 | 7.0 | 9.6 | 10.8 | 14.0 | 15.6 | 18.2 | 20.3 | 22.3 | 24.8 | 27.1 | 30.1 | 33.4 | 37.0 |

| 225 | 6.9 | 7.8 | 10.8 | 12.1 | 15.7 | 17.5 | 20.5 | 22.8 | 25.0 | 27.7 | 30.5 | 33.8 | 37.5 | 41.5 |

| 250 | 7.6 | 8.6 | 12.0 | 13.4 | 17.5 | 19.5 | 22.8 | 25.3 | 27.8 | 30.8 | 33.8 | 37.4 | 41.7 | 46.1 |

| 280 | 8.5 | 9.6 | 13.4 | 15.0 | 19.6 | 21.8 | 25.5 | 28.3 | 31.2 | 34.6 | 37.9 | 41.9 | 46.7 | 51.6 |

| 315 | 9.6 | 10.8 | 15.0 | 16.7 | 22.0 | 24.4 | 28.7 | 31.8 | 35.0 | 38.7 | 42.6 | 47.1 | 52.5 | 58.0 |

| 355 | 10.8 | 12.1 | 17.0 | 18.9 | 24.0 | 27.5 | 32.3 | 35.8 | 39.5 | 43.7 | 48.0 | 53.0 | 59.2 | 65.4 |

| 400 | 12.2 | 14.3 | 19.1 | 22.2 | 28.0 | 32.4 | 36.4 | 42.1 | 44.5 | 51.4 | 54.1 | 62.5 | - | - |

| 450 | 13.7 | 16.0 | 21.5 | 25.0 | 31.4 | 36.4 | 41.0 | 47.4 | 50.0 | 57.7 | - | - | - | - |

| 500 | 15.2 | 17.7 | 23.9 | 27.7 | 34.9 | 40.4 | 45.5 | 52.6 | 55.6 | 64.2 | - | - | - | - |

| 560 | 17.0 | 19.8 | 26.7 | 31.0 | 39.1 | 45.2 | 51.0 | 58.9 | - | - | - | - | - | - |

| 630 | 19.1 | 22.2 | 30.0 | 34.7 | 44.0 | 50.8 | 57.3 | 66.1 | - | - | - | - | - | - |

| 710 | 21.6 | 25.1 | 33.9 | 39.2 | 49.6 | 57.3 | - | - | - | - | - | - | - | - |

| 800 | 24.3 | 28.2 | 38.1 | 44.1 | 55.9 | 64.5 | - | - | - | - | - | - | - | - |

| 900 | 27.3 | 31.6 | 42.9 | 49.6 | - | - | - | - | - | - | - | - | - | - |

| 1000 | 30.4 | 35.2 | 47.7 | 55.1 | - | - | - | - | - | - | - | - | - | - |

| Nominal Diameter | Wall Thickness of Pipes for Pressure Rating of | |||||||||||||

| PN 2.5 | PN 4 | PN 6 | PN 8 | PN 10 | PN 12.5 | PN 16 | ||||||||

| Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | |

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) | (11) | (12) | (13) | (14) | (15) |

| 20 | - | - | - | - | - | - | - | - | - | - | 2.3 | 2.8 | 2.8 | 3.3 |

| 25 | - | - | - | - | - | - | - | - | 2.3 | 2.8 | 2.8 | 3.3 | 3.5 | 4.1 |

| 32 | - | - | - | - | - | - | 2.4 | 2.9 | 3.0 | 3.5 | 3.6 | 4.2 | 4.5 | 5.2 |

| 40 | - | - | - | - | 2.3 | 2.8 | 3.0 | 3.5 | 3.7 | 4.3 | 4.5 | 5.2 | 5.6 | 6.4 |

| 50 | - | - | 2.3 | 2.8 | 2.9 | 3.4 | 3.8 | 4.4 | 4.6 | 5.3 | 5.6 | 6.4 | 6.9 | 7.8 |

| 63 | - | - | 2.5 | 3.0 | 3.6 | 4.2 | 4.7 | 5.4 | 5.8 | 6.6 | 7.0 | 7.9 | 8.7 | 9.8 |

| 75 | - | - | 2.9 | 3.4 | 4.3 | 5.0 | 5.6 | 6.4 | 6.9 | 7.8 | 8.4 | 9.5 | 10.4 | 11.7 |

| 90 | 2.3 | - | 3.5 | 4.1 | 5.1 | 5.9 | 6.7 | 7.6 | 8.2 | 9.3 | 10.0 | 11.2 | 12.5 | 14.0 |

| 110 | 2.7 | 2.5 | 4.3 | 5.0 | 6.3 | 7.2 | 8.2 | 9.3 | 10.0 | 11.2 | 12.3 | 13.8 | 15.2 | 17.0 |

| 125 | 3.1 | 2.9 | 4.9 | 5.6 | 7.1 | 8.1 | 9.3 | 10.5 | 11.4 | 12.8 | 13,9 | 15.5 | 17.3 | 19.3 |

| 140 | 3.5 | 3.5 | 5.4 | 6.2 | 8.0 | 9.0 | 10.4 | 11 | 12.8 | 14.3 | 15.6 | 17.4 | 19.4 | 21.6 |

| 160 | 4.0 | 4.3 | 6.2 | 7.1 | 9.1 | 10.3 | 11.9 | 13.3 | 14.6 | 16.3 | 17.8 | 19.8 | 22.1 | 24.6 |

| 180 | 4.4 | 4.9 | 7.0 | 7.9 | 10.2 | 11.5 | 13.4 | 15.0 | 16.4 | 18.3 | 20.0 | 22.2 | 24.9 | 27.6 |

| 200 | 4.9 | 5.4 | 7.7 | 8.7 | 11.4 | 12.8 | 14.9 | 16.6 | 18.2 | 20.3 | 22.3 | 24.8 | 27.6 | 30.6 |

| 225 | 5.5 | 6.2 | 8.7 | 9.8 | 12.8 | 14.3 | 16.7 | 18.6 | 20.5 | 22.8 | 25.0 | 27.7 | 31.1 | 34.5 |

| 250 | 6.1 | 7.0 | 9.7 | 10.9 | 14.2 | 15.9 | 18.6 | 20.7 | 22.8 | 25.3 | 27.8 | 30.8 | 34.5 | 38.2 |

| 280 | 6.9 | 7.8 | 10.8 | 12.1 | 15.9 | 17.7 | 20.8 | 23.1 | 25.5 | 28.3 | 31.2 | 34.6 | 38.7 | 42.8 |

| 315 | 7.7 | 8.7 | 12.2 | 13.7 | 17.9 | 19.9 | 23.4 | 26.0 | 28.7 | 31.8 | 35.0 | 38.7 | 43.5 | 48.1 |

| 355 | 8.7 | 9.8 | 13.7 | 15.3 | 20.1 | 22.4 | 26.3 | 29.2 | 32.3 | 35.8 | 39.5 | 43.7 | 49.0 | 54.1 |

| 400 | 9.8 | 11.5 | 15.4 | 18.0 | 22.7 | 26.4 | 29.7 | 34.4 | 36.4 | 42.1 | 44.5 | 51.4 | 55.2 | 63.7 |

| 450 | 11.0 | 12.9 | 17.4 | 20.3 | 25.5 | 29.6 | 33.4 | 38.7 | 41.0 | 47.4 | 50.0 | 57.7 | - | - |

| 500 | 12.2 | 14.3 | 19.3 | 22.4 | 28.4 | 32.9 | 37.1 | 42.9 | 45.0 | 52.6 | 55.6 | 64.2 | - | - |

| 560 | 13.7 | 16.0 | 21.6 | 25.2 | 31.7 | 36.7 | 41.5 | 48.0 | 51.0 | 58.9 | - | - | - | - |

| 630 | 15.4 | 18.0 | 24.3 | 28.2 | 35.7 | 41.3 | 46.7 | 54.0 | 57.3 | 66.1 | - | - | - | - |

| 710 | 17.4 | 20.3 | 27.4 | 31.8 | 40.2 | 46.5 | 52.6 | 60.7 | - | - | - | - | - | - |

| 800 | 19.6 | 22.8 | 30.8 | 35.7 | 45.3 | 52.3 | - | - | - | - | - | - | - | - |

| 900 | 22.0 | 25.5 | 34.8 | 40.2 | 51.0 | 58.9 | - | - | - | - | - | - | - | - |

| 1000 | 24.4 | 28.3 | 38.5 | 44.5 | 56.7 | 65.5 | - | - | - | - | - | - | - | - |

| Nominal Diameter | Wall Thickness of Pipes for Pressure Rating of | |||||||||||||

| PN 6 | PN8 | PN 10 | PN 12.5 | PN 16 | ||||||||||

| Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | |||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) | (11) | ||||

| 20 | - | - | - | - | - | - | - | - | 2.3 | 2.8 | ||||

| 25 | - | - | - | - | - | - | 2.3 | 2.8 | 2.9 | 3.4 | ||||

| 32 | - | - | - | - | 2.4 | 2.9 | 2.9 | 3.4 | 3.7 | 4.3 | ||||

| 40 | - | - | 2.4 | 2.9 | 3.0 | 3.5 | 3.7 | 4.3 | 4.6 | 5.3 | ||||

| 50 | 2.3 | 2.8 | 3.0 | 3.5 | 3.7 | 4.3 | 4.6 | 5.3 | 5.7 | 6.5 | ||||

| 63 | 2.9 | 3.4 | 3.8 | 4.4 | 4.7 | 5.4 | 5.7 | 6.5 | 7.1 | 8.1 | ||||

| 75 | 3.5 | 4.1 | 4.5 | 5.2 | 5.6 | 6.4 | 6.8 | 7.7 | 8.5 | 9.6 | ||||

| 90 | 4.1 | 4.8 | 5.4 | 6.2 | 6.7 | 7.6 | 8.2 | 9.3 | 10.2 | 11.5 | ||||

| 110 | 5.0 | 5.7 | 6.6 | 7.5 | 8.1 | 9.2 | 10.0 | 11.2 | 12.4 | 13.9 | ||||

| 125 | 5.7 | 6.5 | 7.5 | 8.5 | 9.2 | 10.4 | 11.3 | 12.7 | 14.1 | 15.8 | ||||

| 140 | 6.4 | 7.3 | 8.4 | 9.5 | 10.3 | 11.6 | 12.7 | 14.2 | 15.8 | 17.6 | ||||

| 160 | 7.3 | 8.3 | 9.6 | 10.8 | 11.8 | 13.2 | 14.5 | 16.2 | 18.1 | 20.2 | ||||

| 180 | 8.2 | 9.3 | 10.8 | 12.1 | 13.3 | 14.9 | 16.3 | 18.2 | 20.3 | 22.6 | ||||

| 200 | 9.1 | 10.3 | 12.0 | 13.4 | 14.8 | 16.5 | 18.1 | 20.2 | 22.6 | 25.1 | ||||

| 225 | 10.3 | 11.6 | 13.5 | 15.1 | 16.6 | 18.5 | 20.4 | 22.7 | 25.4 | 28.2 | ||||

| 250 | 11.4 | 12.8 | 15.0 | 16.7 | 18.4 | 20.5 | 22.6 | 25.1 | 28.2 | 31.3 | ||||

| 280 | 12.8 | 14.3 | 16.8 | 18.7 | 20.6 | 22.9 | 25.3 | 28.1 | 31.6 | 35.0 | ||||

| 315 | 14.4 | 16.1 | 18.9 | 21.0 | 23.2 | 25.8 | 28.5 | 31.6 | 35.5 | 39.3 | ||||

| 355 | 16.2 | 18.1 | 21.2 | 23.6 | 26.2 | 29.1 | 32.1 | 35.6 | 40.0 | 44.2 | ||||

| 400 | 18.2 | 21.2 | 23.9 | 27.7 | 29.5 | 34.2 | 36.2 | 41.9 | 45.1 | 52.1 | ||||

| 450 | 20.5 | 23.8 | 26.9 | 31.2 | 33.1 | 38.3 | 40.7 | 47.1 | 50.8 | 58.7 | ||||

| 500 | 22.8 | 26.5 | 29.9 | 34.6 | 36.8 | 42.6 | 45.2 | 52.2 | 56.4 | 65.1 | ||||

| 560 | 25.5 | 29.6 | 33.5 | 38.8 | 41.2 | 47.6 | 50.6 | 58.4 | - | - | ||||

| 630 | 28.7 | 33.3 | 37.7 | 43.6 | 46.4 | 53.6 | 56.9 | 65.7 | - | - | ||||

| 710 | 32.3 | 37.4 | 42.4 | 49.0 | 52.3 | 60.4 | - | - | - | - | ||||

| 800 | 36.4 | 42.1 | 47.8 | 55.2 | 58.9 | 68.0 | - | - | - | - | ||||

| 900 | 41.0 | 47.4 | 53.8 | 62.1 | - | - | - | - | - | - | ||||

| 1000 | 45.5 | 52.6 | - | - | - | - | - | - | - | - | ||||

We also offer PE Pipes for lowering submersible pumps as it is free of any joints thus installation easy and fast. The Product Details given below

| Standard Diameter (mm) | Coil Length (mtrs) | Application For |

| 32 | 300,500 | Jet Pumps |

| 40 | 200,300,500 | Jet Pumps |

| 50 | 200,300 | Submersible Pumps |

| 63 | 100,200,300 | Submersible Pumps |

| 75 | 100,200,300 | Submersible Pumps |

| 90 | 100 | Submersible Pumps |

| 110 | 50 | Submersible Pumps |

HDPE Pipes for water supply are covered under IS 4984 but the need arose for specific standard of HDPE Pipes for sewerage/industrial effluents and thus IS 14333 was adopted due to following reasons.

These pipes are manufactured from 63mm to 1000mm dia and in material grade PE 63, PE 80 & PE 100 in various pressure ratings.

| Nominal Diameter BL | Wall Thickness of Pipes for Pressure Rating of | |||||||||||||

| PN 2.5 | PN 4 | PN 6 | PN 8 | PN 10 | PN 12.5 | PN 16 | ||||||||

| Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | |

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) | (11) | (12) | (13) | (14) | (15) |

| 63 | - | - | 4.0 | 4.6 | 5.8 | 6.6 | 7.5 | 8.5 | 9.0 | 10.1 | 10.9 | 12.2 | 13.3 | 14.9 |

| 75 | 3.0 | 3.5 | 4.7 | 5.4 | 6.9 | 7.8 | 8.9 | 10.0 | 10.8 | 12.1 | 13.0 | 14.5 | 15.8 | 17.6 |

| 90 | 3.6 | 4.2 | 5.7 | 6.5 | 8.2 | 9.3 | 10.6 | 11.9 | 12.9 | 14.4 | 15.6 | 17.4 | 19.0 | 21.1 |

| 110 | 4.4 | 5.1 | 6.9 | 7.8 | 10.0 | 11.2 | 13.0 | 14.5 | 15.8 | 17.6 | 19.0 | 21.1 | 23.2 | 25.8 |

| 125 | 5.0 | 5.7 | 7.9 | 8.9 | 11.4 | 12.8 | 14.8 | 16.5 | 17.9 | 19.9 | 21.6 | 24.0 | 26.4 | 29.3 |

| 140 | 5.6 | 6.4 | 8.8 | 9.9 | 12.8 | 14.3 | 16.5 | 18.4 | 20.0 | 22.2 | 24.2 | 26.9 | 29.5 | 32.7 |

| 160 | 6.4 | 7.3 | 10.0 | 11.2 | 14.6 | 16.3 | 18.9 | 21.0 | 22.9 | 25.4 | 27.6 | 30.6 | 33.7 | 37.3 |

| 180 | 7.2 | 8.2 | 11.3 | 12.7 | 16.4 | 18.3 | 21.2 | 23.6 | 25.8 | 28.6 | 31.1 | 34.5 | 37.9 | 41.9 |

| 200 | 8.0 | 9.0 | 12.5 | 14.0 | 18.2 | 20.3 | 23.6 | 26.2 | 28.6 | 31.7 | 34.5 | 38.2 | 42.2 | 46.7 |

| 225 | 9.0 | 10.1 | 14.1 | 15.8 | 20,5 | 22.8 | 26.5 | 29.4 | 32.2 | 35.7 | 38.8 | 42.9 | 47.4 | 52.4 |

| 250 | 10.0 | 11.2 | 15.7 | 17.5 | 22.8 | 25.3 | 29.5 | 32.7 | 35.8 | 39.6 | 42.9 | 47.4 | 52.7 | 58.2 |

| 280 | 11.2 | 12.6 | 17.5 | 19.5 | 25.5 | 28.3 | 33.0 | 36.5 | 40.0 | 44.2 | 48.3 | 53.4 | - | - |

| 315 | 12.6 | 14.1 | 19.7 | 21.9 | 28.7 | 31.8 | 37.1 | 41.1 | 45.0 | 49.7 | 54.4 | 60.1 | - | - |

| 355 | 14.2 | 15.9 | 22.2 | 24.7 | 32.3 | 35.8 | 41.8 | 46.2 | 50.8 | 56.1 | - | - | - | - |

| 400 | 16.0 | 18.6 | 25.0 | 29.0 | 36.4 | 42.1 | 47.1 | 54.4 | 57.2 | 66.0 | - | - | - | - |

| 450 | 18.0 | 20.9 | 28.2 | 32.7 | 41.0 | 47.4 | 53.0 | 61.2 | - | - | - | - | - | - |

| 500 | 20.0 | 23.2 | 31.3 | 36.2 | 45.5 | 52.6 | - | - | - | - | - | - | - | - |

| 560 | 22.4 | 26.0 | 35.0 | 40.5 | 51.0 | 58.9 | - | - | - | - | - | - | - | - |

| 630 | 25.2 | 29.2 | 39.4 | 45.6 | 57.3 | 66.1 | - | - | - | - | - | - | - | - |

| 710 | 28.4 | 32.9 | 44.4 | 51.3 | - | - | - | - | - | - | - | - | - | - |

| 800 | 32.0 | 37.0 | 50.0 | 57.7 | - | - | - | - | - | - | - | - | - | - |

| 900 | 36.0 | 41.6 | 56.3 | 65.0 | - | - | - | - | - | - | - | - | - | - |

| 1000 | 40.0 | 46.2 | - | - | - | - | - | - | - | - | - | - | - | |

| Nominal Diameter BL | Wall Thickness of Pipes for Pressure Rating of | |||||||||||||

| PN 2.5 | PN 4 | PN 6 | PN 8 | PN 10 | PN 12.5 | PN 16 | ||||||||

| Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | |

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) | (11) | (12) | (13) | (14) | (15) |

| 63 | - | - | 3.0 | 3.5 | 4.4 | 5.1 | 5.8 | 6.6 | 7.0 | 7.9 | 8.6 | 9.7 | 10.5 | 11.8 |

| 75 | 2.3 | 2.8 | 3.6 | 4.2 | 5.3 | 6.1 | 6.9 | 7.8 | 8.4 | 9.5 | 10.2 | 11.5 | 12.5 | 14.0 |

| 90 | 2.8 | 3.3 | 4.3 | 5.0 | 6.3 | 7.2 | 8.2 | 9.3 | 10.0 | 11.2 | 12.2 | 13.7 | 15.0 | 16.7 |

| 110 | 3.4 | 4.0 | 5.3 | 6.1 | 7.7 | 8.7 | 10.0 | 11.2 | 12.3 | 13.8 | 14.9 | 16.6 | 18.4 | 20.5 |

| 125 | 3.8 | 4.4 | 6.0 | 6.8 | 8.8 | 9.9 | 11.4 | 12.8 | 13.9 | 15.5 | 16.9 | 18.8 | 20.9 | 23.2 |

| 140 | 4.3 | 5.0 | 6.7 | 7.6 | 9.8 | 11.0 | 12.8 | 14.3 | 15.6 | 17.4 | 19.0 | 21.1 | 23.4 | 26.0 |

| 160 | 4.9 | 5.6 | 7.7 | 8.7 | 11.2 | 12.6 | 14.6 | 16.3 | 17.8 | 19.8 | 21.7 | 24.1 | 26.7 | 29.6 |

| 180 | 5.5 | 6.3 | 8.6 | 9.7 | 12.6 | 14.1 | 16.4 | 18.3 | 20.0 | 22.2 | 24.4 | 27.1 | 30.0 | 33.2 |

| 200 | 6.1 | 7.0 | 9.6 | 10.8 | 14.0 | 15.6 | 18.2 | 20.3 | 22.3 | 24.8 | 27.1 | 30.1 | 33.4 | 37.0 |

| 225 | 6.9 | 7.8 | 10.8 | 12.1 | 15.7 | 17.5 | 20.5 | 22.8 | 25.0 | 27.7 | 30.5 | 33.8 | 37.5 | 41.5 |

| 250 | 7.6 | 8.6 | 12.0 | 13.4 | 17.5 | 19.5 | 22.8 | 25.3 | 27.8 | 30.8 | 33.8 | 37.4 | 41.7 | 46.1 |

| 280 | 8.5 | 9.6 | 13.4 | 15.0 | 19.6 | 21.8 | 25.5 | 28.3 | 31.2 | 34.6 | 37.9 | 41.9 | 46.7 | 51.6 |

| 315 | 9.6 | 10.8 | 15.0 | 16.7 | 22.0 | 24.4 | 28.7 | 31.8 | 35.0 | 38.7 | 42.6 | 47.1 | 52.5 | 58.0 |

| 355 | 10.8 | 12.1 | 17.0 | 18.9 | 24.8 | 27.5 | 32.3 | 35.8 | 39.5 | 43.7 | 48.0 | 53.0 | 59.2 | 65.4 |

| 400 | 12.2 | 14.3 | 19.1 | 22.2 | 28.0 | 32.4 | 36.4 | 42.1 | 44.5 | 51.4 | 54.1 | 62.5 | - | - |

| 450 | 13.7 | 16.0 | 21.5 | 25.0 | 31.4 | 36.4 | 41.0 | 47.4 | 50.0 | 57.7 | - | - | - | - |

| 500 | 15.2 | 17.7 | 23.9 | 27.7 | 34.9 | 40.4 | 45.5 | 52.6 | 55.6 | 64.2 | - | - | - | - |

| 560 | 17.0 | 19.8 | 26.7 | 31.0 | 39.1 | 45.4 | 51.0 | 58.9 | - | - | - | - | - | - |

| 630 | 19.1 | 22.2 | 30,0 | 34.7 | 44.0 | 50.8 | 57.3 | 66.1 | - | - | - | - | - | - |

| 710 | 21.6 | 25.1 | 33.9 | 39.2 | 49.6 | 57.3 | - | - | - | - | - | - | - | - |

| 800 | 24.3 | 28.2 | 38.1 | 44.1 | 55.9 | 64.5 | - | - | - | - | - | - | - | - |

| 900 | 27.3 | 31.6 | 42.9 | 49.6 | - | - | - | - | - | - | - | - | - | - |

| 1000 | 30.4 | 35.2 | 47.7 | 55.1 | - | - | - | - | - | - | - | - | - | - |

| -Nominal Diameter | Wall Thickness of Pipes for Pressure Rating of | |||||||||||||

| PN 6 | PN8 | PN 10 | PN 12.5 | PN 16 | ||||||||||

| Min | Max | Min | Max | Min | Max | Min | Max | Min | Max | |||||

| (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) | (11) | ||||

| 63 | 3.6 | 4.2 | 4.7 | 5.4 | 5.8 | 6.6 | 7.0 | 7.9 | 8.7 | 9.8 | ||||

| 75 | 4.3 | 5.0 | 5.6 | 6.4 | 6.9 | 7.8 | 8.4 | 9.5 | 10.4 | 11.7 | ||||

| 90 | 5.1 | 5.9 | 6.7 | 7.6 | 8.2 | 9.3 | 10.0 | 11.2 | 12.5 | 14.0 | ||||

| 110 | 6.3 | 7.2 | 8.2 | 9.3 | 10.0 | 11.2 | 12.3 | 13.8 | 15.2 | 17.0 | ||||

| 125 | 7.1 | 8.1 | 9.3 | 10.5 | 11.4 | 12.8 | 13.9 | 15.5 | 17.3 | 19.3 | ||||

| 140 | 8.0 | 9.0 | 10.4 | 11.7 | 12.8 | 14.3 | 15.6 | 17.4 | 19.4 | 21.6 | ||||

| 160 | 9.1 | 10.3 | 11.9 | 13.3 | 14.6 | 16.3 | 17.8 | 19.8 | 22.1 | 24.6 | ||||

| 180 | 10.2 | 11.5 | 13.4 | 15.0 | 16.4 | 18.3 | 20.0 | 22.2 | 24.9 | 27.6 | ||||

| 200 | 11.4 | 12.8 | 14.9 | 16.6 | 18.2 | 20.3 | 22.3 | 24.8 | 27.6 | 30.6 | ||||

| 225 | 12.8 | 14.3 | 16.7 | 18.6 | 20.5 | 22.8 | 25.0 | 27.7 | 31.1 | 34.5 | ||||

| 250 | 14.2 | 15.9 | 18.6 | 20.7 | 22.8 | 25.3 | 27.8 | 30.8 | 34.5 | 38.2 | ||||

| 280 | 15.9 | 17.7 | 20.8 | 23.1 | 25.2 | 28.3 | 31.2 | 34.6 | 38.7 | 42.8 | ||||

| 315 | 17.9 | 19.9 | 23.4 | 26.0 | 28.7 | 31.8 | 35.0 | 38.7 | 43.5 | 48.1 | ||||

| 355 | 20.1 | 22.4 | 26.3 | 29.2 | 32.3 | 35.8 | 39.5 | 43.7 | 49.0 | 54.1 | ||||

| 400 | 22.7 | 26.4 | 29.7 | 34.4 | 36.4 | 42.1 | 44.5 | 51.4 | 55.2 | 63.7 | ||||

| 450 | 25.5 | 29.6 | 33.4 | 38.7 | 41.0 | 47.4 | 50.0 | 57.7 | - | - | ||||

| 500 | 28.4 | 32.9 | 37.1 | 42.9 | 45.5 | 52.6 | 55.6 | 64.2 | - | - | ||||

| 560 | 31.7 | 36.7 | 41.5 | 48.0 | 51.0 | 58.9 | - | - | - | - | ||||

| 630 | 35.7 | 41.3 | 46.7 | 54.0 | 57.3 | 66.1 | - | |||||||

| 710 | 40.2 | 46.5 | 52.6 | 60.7 | - | - | - | - | - | - | ||||

| 800 | 45.3 | 52.3 | - | - | - | - | - | - | - | - | ||||

| 900 | 51.0 | 58.9 | - | - | - | - | - | - | - | - | ||||

| 1000 | 56.7 | 65.5 | - | - | - | - | - | - | - | - | ||||

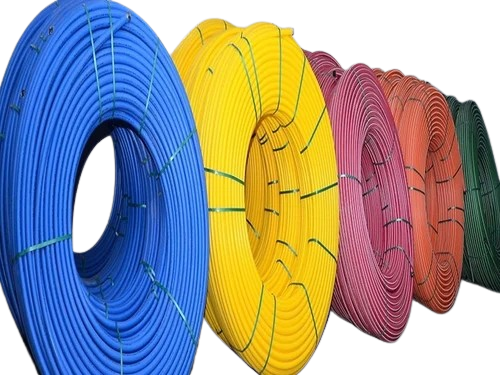

"Tirupati" HDPE PLB Ducts are manufactured from special lubricated compound in various colors like Green,Red ,Orange,Blue.Yellow ,Brown or any other color as per customer requirement.These Pipes have special lubricated compound on the inner side for conveying optical fiber cables at very low friction.

| 32mm / 26mm | 40mm / 33mm | 50mm / 42mm | |

| Noiminal Outside Diameter | 32mm + 0.3mm -0.0mm | 40mm +0.4mm -0.0mm | 50mm +0.5mm -0.0mm |

| Wall Thickness | 3.0mm |

3.5mm |

4mm |

| Thickness of the inner Layer | Min. 0.24mm Max. 0.36mm |

Min. 0.28mm Max. 0.42mm |

Min. 0.32mm Max. 0.48mm |

| Standard Length | 100 meters - 1000 meters (As per customer Requirement) |

100 meters - 1000 meters (As per customer Requirement) |

100 meters - 1000 meters (As per customer Requirement) |

| Maximum outer Diameter of cable that can be installed by blowing technique | 12mm | 16mm | 21mm |

© 2024 Advance Steel Tubes Ltd.